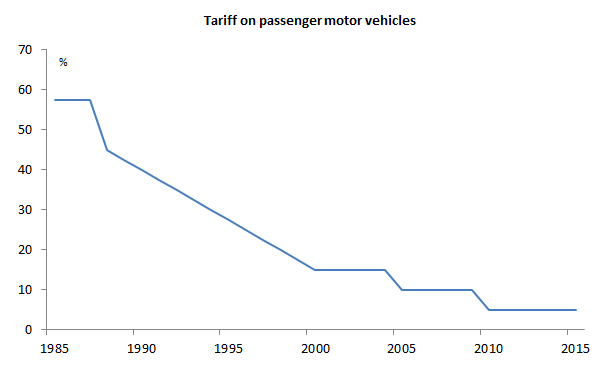

It is the last day of car manufacturing in Australia today, with the final Holden cars to be manufactured at the soon to be shut Elizabeth plant in SA, as reported in the Courier-Mail. It is awful that thousands of people have lost their jobs, but the industry was never viable without the very high tariffs we once had (see chart below), which cost Australian consumers thousands of dollars on every car imported. High tariffs had been replaced by direct industry assistance from taxpayers but, even though it had amounted to in the order of $10,000 per annum per job protected, it was insufficient to save the industry.

There was no legitimate economic case for protecting the car industry, and national defence arguments were spurious. Could we seriously expect a plant once producing Commodores to be rapidly converted to one producing modern fighter jets such as the Joint Strike Fighter? Alas, over the years automotive workers have been given false hope by government policies that had promised to transform and reinvigorate the car industry. Given the small scale of Australia’s domestic car market, which was too small to provide a base level of demand to domestic manufacturers that could support the large capital investments they needed to make, as well as our relatively high labour costs, the shut down of the Australian car industry was always inevitable.

Queenslanders are almost unambiguously better off from the reductions in car industry protection over the last few decades, given most of us benefit from cheaper cars and very few of us would be adversely affected by the plant closures down south.

My previous comments on the car industry include:

Gene, whilst I don’t totally disagree with you I think you make it too simplic. The Australian car industry had four issues apart from a smaller market in my opinion.

1 Labour cost were about 40% higher that comparable skilled jobs. The lack productivity with excessive off work time was also high.

2 Quality was improving but still nowhere near Germam and Japanese built cars.

3 The industry did not read the market well enough as to the type of cars that were actually selling.

4 The occassionly high Australian dollar that played havoc with killing exports and promoting imports of better quality Audis, BMWs and Mazdas. 2012 to 2016.

3 of the 4 of these were controllablle if there was the real desire by the company, governments and unions to keep the industry going.

To me it is a great shame but last week I traded in my 17 year old Commadore, the cheapest car on a KM basis I have ever owned, on a 4 year old Japanese Lexus. Ce la vie.

Russell, yes, you make some great points. Thanks for the comment. Certainly the industry failed to adapt. Its dependence on either high tariffs or direct support from the budget probably reduced its self-reliance and ability to respond to shifting market demands.

One other major change to the market has been the increase in segmentation. In 1978 the Kingswood was the highest selling new vehicle with ~50,000 sales. Last year the Hilux was the highest selling new vehicle with ~40,000 sales. The total number of new vehicles sold per year has more than doubled in that time. That is a big change for a locally focused manufacturer to deal with.

Yes, very good point. Thanks Cameron.

The history of automotive industry policy in Australia is a tribute to the intellectual laziness of the protectionism/free trade debate in Australia. The issues were always much more subtle and interesting. Anyway, a long-running policy nightmare which began with the local content plans of the late 1950s and 60s is finally passed, something for which we can be grateful. And economists will go on believing that making cars in Australia is like making underpants. A mug’s game. What with us being a high wage country and all like Canada, the US, Germany and Japan. Oh wait It’s not true that Australia was poorly suited to making cars but who cares about that when you’re having a good bit of argy bargy in the pub? Those who are interested might like to read an article I wrote on some of this for the Australian Economic review recently.

Click to access When%20only%20the%20second%20best%20will%20do.pdf

Quick quiz apropos of nothing much:

1. Q: Which government body recommended local content plans in 1965 and who was its chairman? A: The Tariff Board the forerunner of the IAC, IC and now PC. The Tariff Board was chaired by Alf Rattigan at the time.

2. Q: What Australian car was exported in larger numbers than were supplied the local market? A: The Mini Moke in 1975.

3. Q: What proportion of Holdens were exported in 1974 (with virtually no assistance and the heavy cost penalties of the local content plan). A: Over 20% to the region, and to Europe. I remember driving around Greece twenty five years ago following a Holden Belmont Ute across the Peloponnese.

NG

Thanks for the comments NG and for the link to your excellent paper, which I am still reflecting on. I agree Howard’s ACIS and Rudd’s new car plan could have been better crafted and targeted. Whether better policies (with the same fiscal impact) could have saved one or two of the manufacturers is an interesting question. Toyota was probably the most viable. We’ll never know now.

Yes, the problem with Toyota was that it was always so technically integrated with other production facilities around the world that they were interchangeable and so lowest costs would eventually win the day. The advantages of the Americans was that they had unique engineering which could have underpinned some unique activity in the international division of automotive labour. But they were never committed to it in a sufficiently serious way – as it wasn’t important to them. So we kicked the can down the road dolling out good money after bad and now they’re all gone. Better off without them in many ways, given that we couldn’t rise to the occasion. At least we’re not dolling out any more money. And as the paper shows, it was a lot of money.

Pingback: Vale: the car industry | Club Troppo